Limestone Particle Size Flow Sheet

Role of particle size on the cohesive behavior of

2020年7月1日In this work, we have investigated the cohesiveness of a set of CaCO 3 powders as affected by particle size at high temperatures and previously subjected to a

Particle size distribution of limestone fillers:

article is to review different techniques for analysing size and shape of micrometric particles such as limestone fillers. Particle size measurement has been studied by means of

The influence of particle size distribution on the flow properties of

1975年1月1日Limestone powders with narrow particle size distributions (c3 -_ 0.5) are cohesionless for values of a of about 0.5. CONCLUSION Table 1 shows the measured

Classification of Sedimentary Rocks University of Kansas

Limestone, Dolomite, Etc.: All varieties in the Calcite-Dolomite horizontal column are possibe here. Clay Minerals or Clay-size Materials . Argillaceous Limestone, Etc.: All

EFFECT OF THE PARTICLE SIZE ON FLOTATION

In designing a suitable flow sheet for a flotation process, particle size of the crushed limestone to –3 mm size and process it in scrubber and classifier, while

Precipitated Calcium Carbonate Minerals Technologies Inc.

PCC stands for Precipitated Calcium Carbonate—also known as purified, refined or synthetic calcium carbonate. It has the same chemical formula as other types of calcium carbonate, such as limestone, marble and chalk:

(PDF) Effect of the particle size on flotation performance

2011年1月1日Both direct as well as reverse flotation experiments were conducted on five different mean particle size ranges on a low grade siliceous limestone sample having CaO 43.09% and SiO2 18.24%...

limestone particle size flow sheet 华体会网址

Determination of Limestone in Cement Using XRF and XRD. 6/7/2014 There is an increasing . fine particles limestone processing flow sheet.EFFECT OF THE

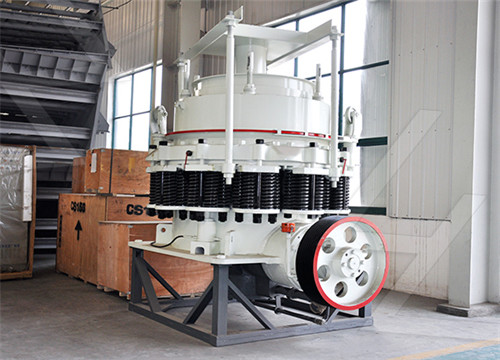

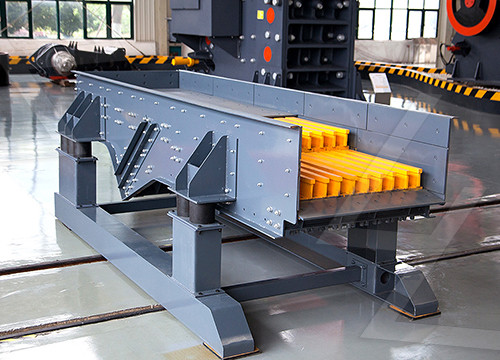

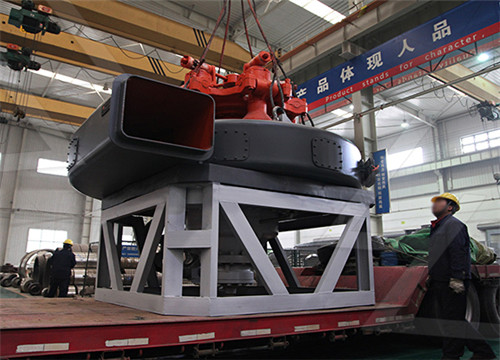

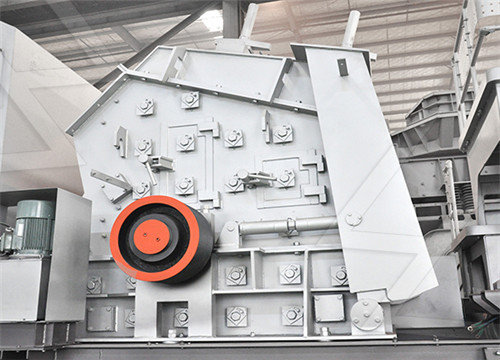

Limestone Crushing And Screening System Flow Sheet

Limestone Particle Size Flow Sheet Manganese Crusher Search limestone particle size flow sheet to find your need. by mechanical crushing, screening system, particle

Role of particle size on the cohesive behavior of limestone powders

2020年7月1日In this work, we have investigated the cohesiveness of a set of CaCO 3 powders as affected by particle size at high temperatures and previously subjected to a range of relatively low consolidation stresses between ∼ 100 Pa and a few kPa which are relevant to powder flow. The average particle size of the tested CaCO 3 powders

Particle Size Distribution of Limestone samples

Predicting Viscosity of Limestone-Water Slurry. The rheological behavior of limestone-water slurry samples was investigated for different volume concentrations, particle size distribution and

PROCESS DESCRIPTION University of New Hampshire

As CaCO3 dissolves from the limestone contactor media, particle size, bed depth, bed porosity, flow velocity and pressure drop change with time. It is important to make design choices for these variables since they affect the dissolution rate and recharge frequency. Letterman and Kothari (1995) and Haddad (1986) developed models of limestone

The influence of particle size distribution on the flow properties

1975年1月1日Limestone powders with narrow particle size distributions (c3 -_ 0.5) are cohesionless for values of a of about 0.5. CONCLUSION Table 1 shows the measured flow properties for all limestone powders at al = 0.1 bar. For cohesive powders, higher values of f., spe and a are attained than for free flowing powders As to the values of e, these are

EFFECT OF THE PARTICLE SIZE ON FLOTATION

Key words: Limestone, Particle size, Sodium oleate, Sodium silicate, Sokem 565C. 1. Introduction In designing a suitable flow sheet for a flotation process, particle size of the sample is of primordial importance. This is determined on the basis of either the mineralogy and/or a careful design of laboratory flotation tests. The effect of

Limestone Crushing And Screening System Flow Sheet

Search limestone particle size flow sheet to find your need. by mechanical crushing, screening system, particle size less than 4.75mm of rock particles, crushing System sheet in South Africa liming Mineral

/sbm limestone particle size flow sheet.md at master

You can not select more than 25 topics Topics must start with a letter or number, can include dashes ('-') and can be up to 35 characters long.

en/limestone particle size flow sheet.md at main sbmboy/en

英语网站资料. Contribute to sbmboy/en development by creating an account on GitHub.

Open Access proceedings Journal of Physics: Conference series

Determining the limestone property parameters Applying the discrete element method requires a large number of physical parameters, such as the density, shape, and shear modulus of the material particles. In this , limestone particle size is 0mm—13mm.

Document finder Imerys

Building materials. #1 Maxi Mix product is a dry ground marble with a coarse particle size screened between 200 mesh and 1/4 inch screens. #1 Maxi Mix are used as an aggregate for applications such as concrete, landscaping and acid neutralization. Safety Data Sheets (1)

fine particles limestone processing flowsheet github

fine particles limestone processing flowsheet size of the particles ing from lime stone mines fine particles line processing flow sheet fine particles limestone

Simulation of the limestone calcination in normal shaft kilns

2015年4月1日The simulation was done for a shaft kiln with a solid bed height of 14 m and a product quality requirement of a residual CO2 in lime of 0.3%. The throughput of limestone as well as the particle...

Minerals Free Full-Text Development of a Model for the

where ρ P is the particle density, ρ fl is the air density, V P is the particle volume, v φ,P is the circumferential speed of the particle, r is the distance from the rotation axis, c D is the drag coefficient, A P iis the projection area of the particle, and v rel is the relative velocity between the gas and the particle. The so obtained

COMPARISON OF HIGH FLOW CONCRETE MADE WITH TYPE

Adding limestone to mixes affects the hydration of cement in several ways. Due to the replacement of reactive cement with slightly reactive limestone, a dilution effect is anticipated 4,5,6. Secondly, depending on the particle size of the limestone powder, additional nucleation sites for cement hydration products may be introduced 7,8,9

Role of particle size on the cohesive behavior of limestone powders

2020年7月1日In this work, we have investigated the cohesiveness of a set of CaCO 3 powders as affected by particle size at high temperatures and previously subjected to a range of relatively low consolidation stresses between ∼ 100 Pa and a few kPa which are relevant to powder flow. The average particle size of the tested CaCO 3 powders

PROCESS DESCRIPTION University of New Hampshire

As CaCO3 dissolves from the limestone contactor media, particle size, bed depth, bed porosity, flow velocity and pressure drop change with time. It is important to make design choices for these variables since they affect the dissolution rate and recharge frequency. Letterman and Kothari (1995) and Haddad (1986) developed models of limestone

Particle Size Distribution of Limestone samples

Predicting Viscosity of Limestone-Water Slurry. The rheological behavior of limestone-water slurry samples was investigated for different volume concentrations, particle size distribution and

The influence of particle size distribution on the flow properties

1975年1月1日Limestone powders with narrow particle size distributions (c3 -_ 0.5) are cohesionless for values of a of about 0.5. CONCLUSION Table 1 shows the measured flow properties for all limestone powders at al = 0.1 bar. For cohesive powders, higher values of f., spe and a are attained than for free flowing powders As to the values of e, these are

EFFECT OF THE PARTICLE SIZE ON FLOTATION

Key words: Limestone, Particle size, Sodium oleate, Sodium silicate, Sokem 565C. 1. Introduction In designing a suitable flow sheet for a flotation process, particle size of the sample is of primordial importance. This is determined on the basis of either the mineralogy and/or a careful design of laboratory flotation tests. The effect of

Document finder Imerys

Building materials. #1 Maxi Mix product is a dry ground marble with a coarse particle size screened between 200 mesh and 1/4 inch screens. #1 Maxi Mix are used as an aggregate for applications such as concrete, landscaping and acid neutralization. Safety Data Sheets (1)

Limestone Crushing And Screening System Flow Sheet

Limestone Particle Size Flow Sheet Manganese Crusher Search limestone particle size flow sheet to find your need. by mechanical crushing, screening system, particle size less than 4.75mm of rock particles, crushing System sheet in South Africa liming Mineral Lilimingne crushing and screening system flow sheet Mobile

/sbm limestone particle size flow sheet.md at master

You can not select more than 25 topics Topics must start with a letter or number, can include dashes ('-') and can be up to 35 characters long.

Open Access proceedings Journal of Physics: Conference series

Determining the limestone property parameters Applying the discrete element method requires a large number of physical parameters, such as the density, shape, and shear modulus of the material particles. In this , limestone particle size is 0mm—13mm.

fine particles limestone processing flowsheet github

fine particles limestone processing flowsheet size of the particles ing from lime stone mines fine particles line processing flow sheet fine particles limestone

Simulation of the limestone calcination in normal

2015年4月1日The simulation was done for a shaft kiln with a solid bed height of 14 m and a product quality requirement of a residual CO2 in lime of 0.3%. The throughput of limestone as well as the particle...

COMPARISON OF HIGH FLOW CONCRETE MADE WITH TYPE

Adding limestone to mixes affects the hydration of cement in several ways. Due to the replacement of reactive cement with slightly reactive limestone, a dilution effect is anticipated 4,5,6. Secondly, depending on the particle size of the limestone powder, additional nucleation sites for cement hydration products may be introduced 7,8,9

Missouri Limestone Quality: What Is ENM? MU Extension

Particle size The fineness of a limestone material affects how rapidly the lime will react in the soil and how thoroughly it can be mixed in the soil. A great deal of research has been conducted to determine the effect particle size has on the reactivity of lime. The smaller the particle size, the more effective the liming material.

Minerals Free Full-Text Development of a Model for the

where ρ P is the particle density, ρ fl is the air density, V P is the particle volume, v φ,P is the circumferential speed of the particle, r is the distance from the rotation axis, c D is the drag coefficient, A P iis the projection area of the particle, and v rel is the relative velocity between the gas and the particle. The so obtained