Coal Grinding Mill In Cement Plant

Coal Mills for Cement Plants Loesche

LOESCHE coal grinding mills are distinguished by characteristics that improve efficiency, safety and environmental protection, from the standard version to top-of-the-range installations. Special versions are available

Coal Mill in Cement Plant

Coal Mill in Cement Plant A coal mill is also called a coal pulverizer or coal grinder. It is a mechanical device used to grind raw coal into pulverized coal powders. The most used

进一步探索

Coal Mills in Thermal Power Plant PDF Mill (Grinding) Coal mill pulverizer in thermal power plants SlideShare根据热度为您推荐•反馈

Coal Mill Coal Mill In Cement Plant AGICO Cement Equipment

The coal mill grinding system is an important part of the dry process cement manufacturing. In cement plants, we usually adopt the air swept coal mill system or

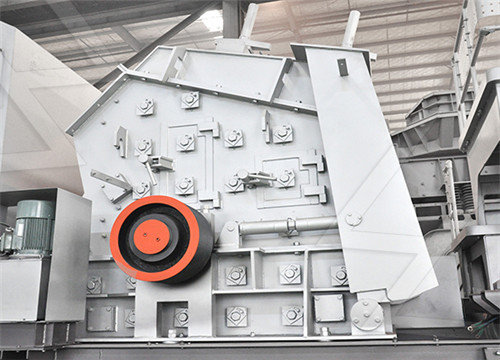

Vertical Coal Mill for Coal Grinding in Cement Plant

Applications: Vertical coal mill is mainly used for grinding raw coal, bituminous coal, and other fuels into coal powder, which is supplied to

Coal Mill an overview ScienceDirect Topics

Most milling operations focus on four mechanisms that occur in a coal mill system: 1. Comminution (size reduction); 2. Drying; 3. Transport of material; 4. Classification.

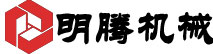

Air Swept Coal Mill Coal Mill In Cement Plant AGICO GROUP

The air-swept coal mill is also called a coal grinder. It is the main equipment of the cement plant, used for drying and pulverizing coal powder. It mainly consists of the feeding

Coal Mill In Cement Plant, Air-swept Coal Mill Coal Mill

Air-swept coal mill is the main equipment of cement plant, also called coal mill in cement plant, used for grinding and drying various hardness of coal, crushing the coal

Cement mill Wikipedia

A cement mill (or finish mill in North American usage [1]) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement. Most cement is currently ground in ball

Cement Grinding Unit Cement Grinding Plant

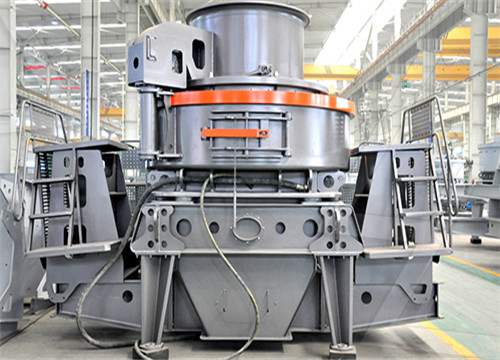

The cement grinding machine includes cement vertical mill, cement ball mill, cement roller press, cement seperator, conveyor and other cement equipment. We can provide scheme design for free according to the

Coal Grinding Mill in Cement Plant Ore Milling Plant

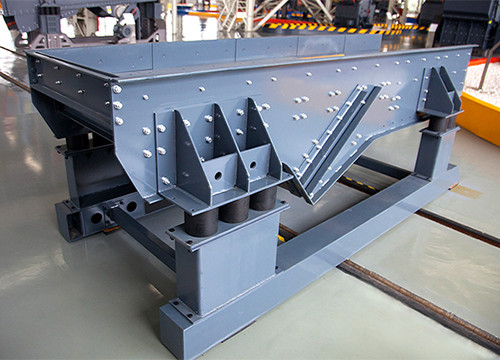

Coal mill is major equipment of cement plant and used for drying and grinding coal. The equipment is mainly consisted of feed device, main bearings, rotating parts, drive device,

ATOX coal mill

The ATOX coal mill is suited for various installation types, whether inert or non-inert, and direct or indirect firing systems. An inert system designed for indirect firing is the most common solution for cement plants. Equipped with the high-efficiency RAKM dynamic separator, the ATOX coal mill will grind any type of coal to the required

Vertical Roller Mills

Grinding systems in cement production make up approximately 85 to 90 percent of total plant electrical energy consumption. As vertical roller mills are 30 to 50 percent more efficient than other grinding solutions, they

Coal Mill an overview ScienceDirect Topics

Most milling operations focus on four mechanisms that occur in a coal mill system: 1. Comminution (size reduction); 2. Drying; 3. Transport of material; 4. Classification. Failure to understand all four and their inter-relationship is most often the

Coal Mills for Cement Plants Loesche

LOESCHE coal grinding mills are distinguished by characteristics that improve efficiency, safety and environmental protection, from the standard version to top-of-the-range installations. Special versions are available with characteristics that meet special safety regulation or output control requirements. REFERENCES. PLANT SIZES.

BASIC CEMENT PLANT LAYOUT Process Cement

2020年7月4日The coal mill building houses the mill for grinding lumpy coals. This fine ground coal is used for burning in the kiln. The mills used for coal grinding and drying are either trumbling mills (tube mills) or

Emergency inerting systems for coal-grinding applications

2011年10月21日In the case of coal-grinding or storage (as one might find in a cement plant) it is not possible to remove the fuel (coal) or ignition source (grinding energy, heat, static charges) and so one has to concentrate on removing the third necessary component O 2. This fact has given rise to inerting systems that rely on the use of inert gases.

DISCUSSION ON SAFETY PRODUCTION OF COAL MILLING SYSTEM IN CEMENT PLANT

2022年1月27日In the current cement production process, a large amount of fuel is also required as a guarantee, and coal is the main fuel. The burn-up of coal in cement production requires the support of...

Grinding Mill Grinding Equipment Cement Mill

The ultrafine grinding system manufactured by AGICO is mainly used for grinding pulverized coal and cement. In order to meet the need for further grinding and 3D printing, in 2015, our company built an ultrafine powder

Coal Mill Safety

When it comes to coal mill systems, most cement plant operators just presume that the supplier of the equipment knows all of the standards and rules and is 100% capable of making a system that conforms to these

ru/roller mill цемент нунтаглах.md at main yeahliangyy/ru

Contribute to yeahliangyy/ru development by creating an account on GitHub.

Ball Mill In Cement Plant Cement Ball Mill AGICO Cement

In addition, the closed-circuit grinding system has the characteristic of high efficiency, high output, low cement temperature, and good comprehensive benefit. Generally, the output of the closed-circuit ball mill is 15% ~ 25% higher than that

Coal Dust Explosions in the Cement Industry Texas A&M

coal grinding, drying, blending.transporting, and storing. Case histories investigated by the Mine Safety and Health Administration (MSHA) will be discussed, and recommendations will be made for future fire and explosion prevention. KEY WORDS: coal dust, fires and explosions, cement plants, coal fired systems, safety

Thomas Holzinger Consulting of Cement Mill Grinding Process

Cement Mill Core Consultation Scopes. Grinding and Classification of Cement and Minerals; Plant Layout, Design for Ground Calcium Carbonates, Raw Material, Solid Fuels and Cement; Equipment Specification of mills, classifiers, transports. Process Control Systems High Level Control; Wear Strategies for Ball Mills, Roller Presses and Vertical

Coal for cement: Present and future trends Global Cement

2016年3月1日Next, in November 2014, Titan Cement ordered a Gebr. Pfeiffer SE type MPS 2800 BK vertical roller mill for coal grinding, to be set up at line 1 at its Beni Suef plant. In January 2015, Suez Cement, Italcementi’s Egyptian arm, said that it would spend US$84m during the year to convert its Helwan and Tourah 2 cement plants to use coal.

ATOX coal mill

The ATOX coal mill is suited for various installation types, whether inert or non-inert, and direct or indirect firing systems. An inert system designed for indirect firing is the most common solution for cement plants. Equipped with the high-efficiency RAKM dynamic separator, the ATOX coal mill will grind any type of coal to the required

Vertical Roller Mills

Grinding systems in cement production make up approximately 85 to 90 percent of total plant electrical energy consumption. As vertical roller mills are 30 to 50 percent more efficient than other grinding solutions, they

Coal Mill an overview ScienceDirect Topics

Most milling operations focus on four mechanisms that occur in a coal mill system: 1. Comminution (size reduction); 2. Drying; 3. Transport of material; 4. Classification. Failure to understand all four and their inter-relationship is most often the

Coal Mills for Cement Plants Loesche

LOESCHE coal grinding mills are distinguished by characteristics that improve efficiency, safety and environmental protection, from the standard version to top-of-the-range installations. Special versions are available with characteristics that meet special safety regulation or output control requirements. REFERENCES. PLANT SIZES.

Coal for cement: Present and future trends Global Cement

2016年3月1日Next, in November 2014, Titan Cement ordered a Gebr. Pfeiffer SE type MPS 2800 BK vertical roller mill for coal grinding, to be set up at line 1 at its Beni Suef plant. In January 2015, Suez Cement, Italcementi’s Egyptian arm, said that it would spend US$84m during the year to convert its Helwan and Tourah 2 cement plants to use coal.

Grinding Mill Grinding Equipment Cement Mill

The air swept coal mill is the main equipment of cement plant, usually used for drying and pulverizing coal. It is mainly composed of the feeding device, main bearing, transmission device, discharging device and the

DISCUSSION ON SAFETY PRODUCTION OF COAL MILLING SYSTEM IN CEMENT PLANT

2022年1月27日In the current cement production process, a large amount of fuel is also required as a guarantee, and coal is the main fuel. The burn-up of coal in cement production requires the support of...

Coal Dust Explosions in the Cement Industry Texas A&M

coal grinding, drying, blending.transporting, and storing. Case histories investigated by the Mine Safety and Health Administration (MSHA) will be discussed, and recommendations will be made for future fire and explosion prevention. KEY WORDS: coal dust, fires and explosions, cement plants, coal fired systems, safety

Thomas Holzinger Consulting of Cement Mill Grinding Process

Cement Mill Core Consultation Scopes. Grinding and Classification of Cement and Minerals; Plant Layout, Design for Ground Calcium Carbonates, Raw Material, Solid Fuels and Cement; Equipment Specification of mills, classifiers, transports. Process Control Systems High Level Control; Wear Strategies for Ball Mills, Roller Presses and Vertical

ru/roller mill цемент нунтаглах.md at main yeahliangyy/ru

Contribute to yeahliangyy/ru development by creating an account on GitHub.

Emergency inerting systems for coal-grinding applications

2011年10月21日In the case of coal-grinding or storage (as one might find in a cement plant) it is not possible to remove the fuel (coal) or ignition source (grinding energy, heat, static charges) and so one has to concentrate on removing the third necessary component O 2. This fact has given rise to inerting systems that rely on the use of inert gases.

Ball Mill In Cement Plant Cement Ball Mill AGICO Cement

In addition, the closed-circuit grinding system has the characteristic of high efficiency, high output, low cement temperature, and good comprehensive benefit. Generally, the output of the closed-circuit ball mill is 15% ~ 25% higher than that

Adaptation of the ball race mill technology for wet comminution

Vertical Roller Mill (VRM) technology was developed more than four decades ago and has found applications mostly in cement grinding operations and in power plants for coal grinding. VRM technology has been well documented in literature to offer energy consumption reduction (from 15% to 30%) over conventional comminution units and circuits.

CEMENT PLANT TALK-001

Coal Mill: Mill Bag filter jamming. Kiln Fluctuating Free lime in clinker. Such type of problem is quite common in cement plants and are responsible for daily kiln disturbances, mill feed variations and higher heat, power, grinding media, refractory consumptions in cement plant. For all grinding mills like ball mills, vertical roller