Speed Switch At Primary Crusher In Copper Mine

[PDF] Primary crusher site selection in open pit mines: Case study

2021年6月30日Facility site selection, (such as Primary or in pit Crusher location) is one of the most important steps in mine design process that has a significant impact on

Primary Crusher SelectionDesign Mineral Processing

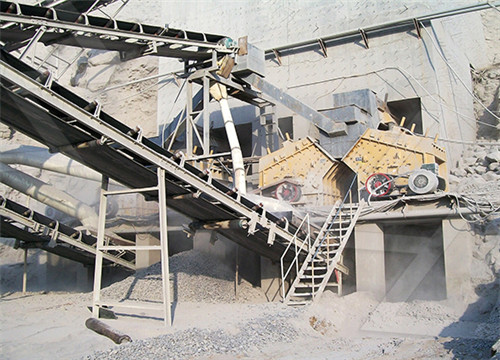

2015年12月23日In in-pit crushing, the primary function of a crusher is to provide a smaller uniform product size for each of transport by the

Primary Crushing Mineral ProcessingMetallurgy

2016年2月26日A crusher of these dimensions will break 40 tons per hour to 2½-in. size with a power consumption of 30 h.p. On the other hand, a

Los Bronces Copper and Molybdenum Mine Mining

Los Bronces Mine GeologyReserves and Production at Los BroncesRecent Developments and Expansions at Los Bronces MineLos Bronces Development Project DetailsMining at Los Bronces

The existing ore reserve at Los Bronces, as of 31 December 2011, stood at 2.17 billion tons (bt) grading 0.62% Cu (11.5mt of contained copper). Los Bronces produced 221,800t of copper in 2011 and 221,400t in 2010. Copper cathode comprised 38,400t, while copper in sulphate accounted for 4,600t. Copper concentrate production during 2011 was 178,800t....

(PDF) Throughput Forecasting and Optimisation at the

2014年9月1日Throughput modelling and forecasting indicates that later in the mine life Phu Kham will become SAG mill limited rather than primary crusher limited due to

Morenci Copper Mine, Arizona, USA Mining Technology

2022年9月1日The mine area spanned more than 61,700 acres as of 31 December 2021. Operations at the open-pit mine are expected to continue until 2041. The mine employs

Belzona reinforces crusher foundations at Brazil copper mine

2019年5月13日Concrete repair and rebuild composite comes to the rescue of Brazil copper miner worried about foundations of primary crusher. Open menu. The Electric

Copper Mountain Mine Primary Crusher Building My CMS

Copper Mountain Mine Primary Crusher Building Previous Next 1 2 Project Description Location: Princeton, British Columbia (BC) LoadPath is once again back up at Copper

Major MinesProjects Copper Mountain Expansion

Summary: Mining at the Copper Mountain Mine is by conventional open pit methods, using a 15-m bench height. The major components of this mining method are blasthole drilling,

PRIMARY CRUSHER SITE SELECTION IN OPEN PIT MINES

underground mining engineering 38 (2021) 15-25 udk 62 university of belgrade faculty of mining and geology issn original scientific stone primary crusher site selection in open pit

(PDF) Primary crusher site selection in open pit mines:

2021年1月1日This study covers an attempt to find the optimal location for primary crusher in order to support the expansion of Sungun copper mine, which is the second largest open pit mine in Iran. Recent

Minera Los Pelambres Mining Technology

2018年12月21日The mine is operated in two 12-hour shifts. Copper processing Trucks feed an FFE Minerals 60in x 110in primary gyratory crusher, while a sophisticated overland conveyor system engineered by

Industrial Solutions Gyratory crushers ThyssenKrupp

crusher configuration. The feed material should be at least 20% smaller than the width of the feed open ing. Arrangement drawing with fitting dimensions and loads on request. Large feed opening 3,080 x 1,675 mm Jaw gyratory crusher for underground iron ore mining and the crushing chamber of a BK 63-75 in a stationary copper ore plant

Gyratory Crusher Explained saVRee

An external gearbox or belt drive arrangement reduces the motor speed to approximately 100-200 RPM at the crusher. In some cases, a clutch system may also be used to absorb shocks. The pinion on the countershaft

What Type of Crusher Is Best for Primary Crushing?

2021年3月25日Feeder-Breakers. Feeder-Breakers, which combine both feeding and crushing into one machine, are used for the primary crushing of friable materials that can be slightly abrasive, dry or wet, but not

Morenci Copper Mine, Arizona, USA Mining

2022年9月1日The mineralisation extends 8km in a north-south direction and 6.43km in an east-west direction. The proven and probable reserves of the mine were estimated at 11.13 billion tonnes, grading 0.24% copper,

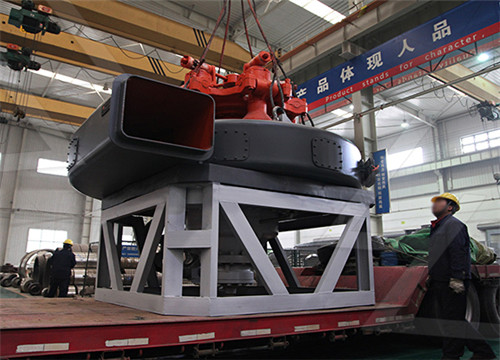

Copper Mountain Mine Primary Crusher Building

LoadPath is once again back up at Copper Mountain Mine, selected to construct the latest mine building, a 4,000 sq.ft. x 110 ft tall Coarse Ore Stockpile Feed Primary Crusher building.

A net-zero mine? Copper Mountain takes electrifying first step

2022年1月31日But move they do, at a speed of up to 35 km/h, more than double the top speed of what the diesel motor can manage. The BC Hydro Interconnections team worked throughout 2021 to ensure that Copper Mountain can access the additional load needed to power the project.

Fuzzy TOPSIS method to primary crusher selection for Golegohar

2014年11月15日Selection of suitable primary crusher from all of available primary crushers is a multi-criterion decision making (MCDM) problem. The present work explores the use of technique for order performance by similarity to ideal solution (TOPSIS) with fuzzy set theory to select best primary crusher for Golegohar Iron Mine in Iran.

Fuzzy TOPSIS method to primary crusher selection for Golegohar

2014年11月1日Results of the work based on fuzzy TOPSIS method show that the gyratory is the best primary crusher for the studied mine. Selection of the crusher required a great deal of design regarding to the mine planning. Selection of suitable primary crusher from all of available primary crushers is a multi-criterion decision making (MCDM) problem.

Productos Asarco

Improved conductivity means more energy is delivered to the desired destination when you flip that switch or turn that dial. COPPER IS RECYCLABLE More than one-third of the copper refined in the United States comes from recycled material. That’s a higher recycling rate than aluminum!

AMIT 135: Lesson 6 Grinding Circuit Mining Mill Operator

AG/SAG mills are normally used to grind run-off-mine ore or primary crusher product. Wet grinding in an AG/SAG mill is accomplished in a slurry of 50 to 80 percent solids. 2D and 3D simulations of particles in a SAG Mill red=fastest, blue=slowest moving particles [image: (135

Ivanhoe Mines installs new primary crusher as underground

2018年5月29日Ivanhoe Mines installs new primary crusher as underground mine upgrading work nears completion at the historic Kipushi zinc-copper-silver-germanium mine in the Democratic Republic of...

PRIMARY CRUSHER SITE SELECTION IN OPEN PIT MINES

underground mining engineering 38 (2021) 15-25 udk 62 university of belgrade faculty of mining and geology issn original scientific stone primary crusher site selection in open pit

(PDF) Primary crusher site selection in open pit mines:

2021年1月1日This study covers an attempt to find the optimal location for primary crusher in order to support the expansion of Sungun copper mine, which is the second largest open pit mine in Iran. Recent

[PDF] Primary crusher site selection in open pit mines: Case

2021年6月30日This study covers an attempt to find the optimal location for primary crusher in order to support the expansion of Sungun copper mine, which is the second largest open pit mine in Iran. Recent exploration drilling has led to a considerable increase in the ore reserve. Therefore, Sungun started the studies followed with an expansion

Industrial Solutions Gyratory crushers ThyssenKrupp

crusher configuration. The feed material should be at least 20% smaller than the width of the feed open ing. Arrangement drawing with fitting dimensions and loads on request. Large feed opening 3,080 x 1,675 mm Jaw gyratory crusher for underground iron ore mining and the crushing chamber of a BK 63-75 in a stationary copper ore plant

What Type of Crusher Is Best for Primary Crushing?

2021年3月25日The primary crushing stage at the top of the machine and the secondary stage at the bottom of the machine both consist of a double-roll arrangement. Due to the feed opening and design of the top stage,

Productos Asarco

Improved conductivity means more energy is delivered to the desired destination when you flip that switch or turn that dial. COPPER IS RECYCLABLE More than one-third of the copper refined in the United

Belzona reinforces crusher foundations at Brazil

2019年5月13日Concrete repair and rebuild composite comes to the rescue of Brazil copper miner worried about foundations of primary crusher. Open menu. The Electric Mine 2023; IPCC 2022; Event

Copper Mountain Mine Primary Crusher Building

LoadPath is once again back up at Copper Mountain Mine, selected to construct the latest mine building, a 4,000 sq.ft. x 110 ft tall Coarse Ore Stockpile Feed Primary Crusher building.

Pinto Valley Capstone Copper

Pinto Valley has been in operation since 1972 and has produced more than four billion pounds of copper since then. Capstone acquired it from BHP in October 2013. The operation consists of an open-pit mine, a 60,000 tonnes per day (“tpd”) concentrator plant and a 25,000 tpd SX-EW plant. Pinto Valley is currently the only operating mill and

Fuzzy TOPSIS method to primary crusher selection for Golegohar

2014年11月15日Selection of suitable primary crusher from all of available primary crushers is a multi-criterion decision making (MCDM) problem. The present work explores the use of technique for order performance by similarity to ideal solution (TOPSIS) with fuzzy set theory to select best primary crusher for Golegohar Iron Mine in Iran.

AMIT 135: Lesson 6 Grinding Circuit Mining Mill Operator

Primary, coarse grinding (up to 400 mm feed size) Grinding media is grinding feed plus 4-12% ball charge (ball dia.100- 125 mm) High capacity (short retention time) Less sensitive to feed composition (critical size material) Semi-Autogenous Mill Note the size of the mill: Why does the diameter need to be so big? [image: (135-6-2)]

to deliver the world’s largest gyratory crusher

2023年1月3日 has been chosen to supply the world’s highest capacity in-pit crushing system to a leading copper miner in South America to boost its efficiency. The order is valued at approximately

Cone Crusher Explained saVRee

Mining using explosives was referred to as blasting. By the mid-1800s, blasting was a widespread mining technique used for bulk mining and it would be shortly followed by steam shovelling. These new mining techniques revolutionised the mining industry, allowing for the production of ever larger amounts of liberated materials.