Grinding Processing Fields

Machining 101: What is Grinding? Modern Machine Shop

2021年7月3日Grinding process control balances these three interactions to achieve the desired parameters. These interactions feed into three

Technologies in Exploration, Mining, and Processing

These fields sometimes overlap, and developments in one area are likely to cross-fertilize research and development in other areas. Dry grinding, a higher cost process than

What is Grinding ProcessHow It Works Different Types of

2022年11月28日It refers to the cutting process of the workpiece surface with a high-speed rotating grinding wheel and other abrasive tools. Grinding is used to process

Analysis of grinding process with the use of field theory

2020年1月3日fields is characterized respectively efficiency of machining and destruction of an instrument’s working area 1. Introduction There is a wide variety of types of

GrindingMilling: 2 Most Basic Machining Processes

Grinding is used in processing various types of materials, such as metals, , composites, and . Grinding and milling are commonly used to produce powder

What is Grinding Process? ExtruDesign

2022年5月29日In metal works, Grinding is the metal removal process by the application of abrasives which are bonded to form a rotating wheel. In this grinding process, the

Grinding Machining Process : Complete Notes Mech4study

This process is known as Dressing of grinding wheel and the whole process takes 15 to 20 minutes to operate. The life of the grinding wheel is described as the time period

Effect of the surface micro-structures on strength and

2022年12月15日While in the micro flow field, the simulation mainly studies the effects of surface morphology, micro-groove structure parameters and grinding parameters on the

AMIT 135: Lesson 6 Grinding Circuit Mining Mill

Objectives. At the end of this lesson students should be able to: Explain the grinding process. Distinguish between crushing and grinding. Compare and contrast different type of equipment and their components used for

Effects of traditional grinding and superfine grinding

2023年1月1日Therefore, superfine grinding technology has been widely studied and used in various processing fields (Wang et al., 2020), such as in the production of Lentinus edodes and Lycium ruthenicum Murray powders (Ming, Chen, Hong,Li, 2015; Zhang et al., 2020). In recent years, based on superfine grinding technology, researchers have

Technologies in Exploration, Mining, and Processing

The three major components of mining (exploration, mining, and processing) overlap somewhat. After a mineral deposit has been identified through exploration, the industry must make a considerable investment in mine development before production begins.

Grinding, sanding, polishing, deburring FerRobotics

GRINDING FerRobotics is technology leader in automated surface processing and has in-depth application know-how in robotized grinding and sanding. The sophisticated product range offers a multitude of tailor

Effect of the surface micro-structures on strength and flow field

2022年12月15日While in the micro flow field, the simulation mainly studies the effects of surface morphology, micro-groove structure parameters and grinding parameters on the grinding zone flow field. Take the grinding process of the blind hole with 0.3 mm depth and 0.3 mm diameter as an example, the following assumptions are made for the macro

Modeling of heat source in grinding zone and numerical

2019年5月3日To accurately predict temperature field changes of the subsurface of the workpiece, a heat source model of the contact zone in the real grinding process is established using the temperature matching method according to the principle of anti-heat source and the actually measured grinding temperature. The finite element method is

(PDF) Temperature Field of Open-Structured

2020年6月9日In order to explore this grinding heat accumulation process, a 3D finite element model (FEM) of multi-abrasive scratching was established to analyse the grinding temperature field on the rail surface.

Grinding Mills Common Types Mineral

2016年11月7日In Fig. 1.3 is shown a large ball mill, designed for the dry grinding of limestone, dolomite, quartz, refractory and similar materials; this type of mill being made in a series of sizes having diameters ranging

Materials Free Full-Text Metrological Aspects of Assessing

The stone presents probabilistic aspects of diagnostics of grinding processes with consideration of metrological aspects of evaluation of topography of machined surfaces and selected problems of assessment of machining accuracy. The processes of creating the geometric structure of the ground surface are described. It was pointed out that the

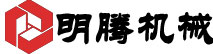

The Most Effective Lithium Ore Processing Method You Must Know

2023年2月15日An effective lithium ore processing plant mainly includes crushing line, grinding line, beneficiation line, and some auxiliary equipment. The most commonly used production equipment is crusher (jaw crusher, impact crusher, cone crusher), ball mill, flotation machine or magnetic separator, etc.

Hunting, processing, and serving black bear

Sauté meat until it loses its color. Add onions, garlic, celery, and pepper and cook until onion is soft. Stir in the spices and cook until absorbed. Add water, bring to a boil, reduce heat, cover, and simmer for 1½ hours or

Metallographic method for temperature measurement:

2022年9月1日Grinding is the main processing technique for particle-reinforced composites, in which grinding force and temperature are significant for investigating the removal mechanism and surface properties.

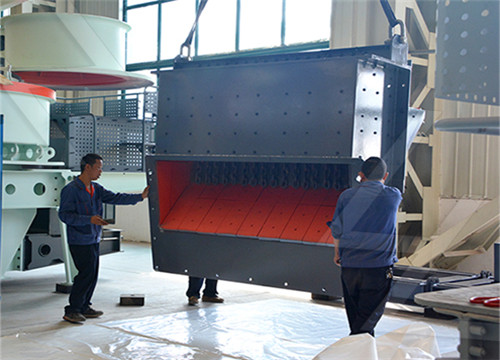

Grinding mill services Metso Outotec

Field services. Maintenance, repairs, installations, and shutdowns for grinding circuits can be large and complicated jobs. Metso Outotec grinding equipment and process specialists use ore characterization data, comprehensive plant surveys, and historical operational data to develop site-specific models for your comminution processes. These

The temperature field study on the annular heat source model in

2017年7月15日Most of the current studies focus on the moving heat source model of straight wheel. However, these cannot be applied to calculate the cup wheel grinding temperature field, especially for the grinding processes performed with an adaptive end-effector. Based on the moving heat method and the principle of heat source

POST HARVESTING PROCESSING Food and Agriculture

Primary processing of cereals includes cleaning, grading, hulling, milling, pounding, g rinding, tempering, parboiling, soaking, drying, sieving. Secondary processing of cereals (or 'adding value' to cereals) is the utilisation of the primary products (whole grains, flakes or ) to make more interesting products and add variety to the diet.

Effects of traditional grinding and superfine grinding

2023年1月1日Therefore, superfine grinding technology has been widely studied and used in various processing fields (Wang et al., 2020), such as in the production of Lentinus edodes and Lycium ruthenicum Murray powders (Ming, Chen, Hong,Li, 2015; Zhang et al., 2020). In recent years, based on superfine grinding technology, researchers have

Effect of the surface micro-structures on strength and flow field

2022年12月15日While in the micro flow field, the simulation mainly studies the effects of surface morphology, micro-groove structure parameters and grinding parameters on the grinding zone flow field. Take the grinding process of the blind hole with 0.3 mm depth and 0.3 mm diameter as an example, the following assumptions are made for the macro

Modeling of heat source in grinding zone and numerical

2019年5月3日To accurately predict temperature field changes of the subsurface of the workpiece, a heat source model of the contact zone in the real grinding process is established using the temperature matching method according to the principle of anti-heat source and the actually measured grinding temperature. The finite element method is

Metallographic method for temperature measurement:

2022年9月1日Grinding is the main processing technique for particle-reinforced composites, in which grinding force and temperature are significant for investigating the removal mechanism and surface properties.

Grinding Mills Common Types Mineral

2016年11月7日In Fig. 1.3 is shown a large ball mill, designed for the dry grinding of limestone, dolomite, quartz, refractory and similar materials; this type of mill being made in a series of sizes having diameters ranging

Materials Free Full-Text Metrological Aspects of Assessing

The stone presents probabilistic aspects of diagnostics of grinding processes with consideration of metrological aspects of evaluation of topography of machined surfaces and selected problems of assessment of machining accuracy. The processes of creating the geometric structure of the ground surface are described. It was pointed out that the

(PDF) Temperature Field of Open-Structured

2020年6月9日In order to explore this grinding heat accumulation process, a 3D finite element model (FEM) of multi-abrasive scratching was established to analyse the grinding temperature field on the rail surface.

The Most Effective Lithium Ore Processing Method You Must Know

2023年2月15日An effective lithium ore processing plant mainly includes crushing line, grinding line, beneficiation line, and some auxiliary equipment. The most commonly used production equipment is crusher (jaw crusher, impact crusher, cone crusher), ball mill, flotation machine or magnetic separator, etc.

Hunting, processing, and serving black bear

Sauté meat until it loses its color. Add onions, garlic, celery, and pepper and cook until onion is soft. Stir in the spices and cook until absorbed. Add water, bring to a boil, reduce heat, cover, and simmer for 1½ hours or

POST HARVESTING PROCESSING Food and Agriculture

Primary processing of cereals includes cleaning, grading, hulling, milling, pounding, g rinding, tempering, parboiling, soaking, drying, sieving. Secondary processing of cereals (or 'adding value' to cereals) is the utilisation of the primary products (whole grains, flakes or ) to make more interesting products and add variety to the diet.

The temperature field study on the annular heat source model in

2017年7月15日Most of the current studies focus on the moving heat source model of straight wheel. However, these cannot be applied to calculate the cup wheel grinding temperature field, especially for the grinding processes performed with an adaptive end-effector. Based on the moving heat method and the principle of heat source

Phase transformation and deformation of the high-frequency

2023年1月24日During the grinding process, the grinding wheels play the crucial role in obtaining a high-quality ground surface. With the characteristics of rapid heating and rapid cooling, the induction brazing is a complex process involving multi-field coupling such as electromagnetics field, temperature field, stress–strain field, and microstructure

Mobile Rail Grinding voestalpine Railway Systems

voestalpine Track Solutions Germany GmbH operates several RGH 20C on-track grinding machines. Thanks to the flexibility of these machines, they may be used for preventive and corrective maintenance as well as initial grinding on rail in turnouts, connecting tracks, level crossings and other limited areas. The integrated measurement and testing

Grinding mill services Metso Outotec

Field services. Maintenance, repairs, installations, and shutdowns for grinding circuits can be large and complicated jobs. Metso Outotec grinding equipment and process specialists use ore characterization data, comprehensive plant surveys, and historical operational data to develop site-specific models for your comminution processes. These