High Pressure Medium Speed Cement Vertical Grinding Mill Cement Vertical Mill

PROCESS CONTROL FOR CEMENT GRINDING IN VERTICAL

The power ingesting of a grinding process is 50-60% in the cement production power consumption. The Vertical Roller Mill (VRM) reduces the power consumption for

Vertical Cement Mill Cement Clinker Grinding Equipment in

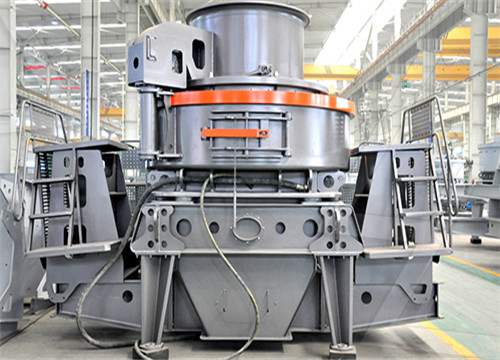

Vertical Cement Mill Feeding size: ≤110mm Capacity: 55-250t/h Motor power: 1250-5300kW Applications: It mainly used in the cement clinker

Cement Vertical Mill Vertical Grinding Mill Vertical Mill AGICO

The cement vertical mill is grinding equipment developed on the basis of similar grinding mills, so it has many irreplaceable advantages, such as high grinding efficiency, low

Vertical grinding mills SKF SKF

Cement making Vertical grinding mills Vertical grinding mills Heat and risk of contamination make it difficult to keep equipment up and running. Avoid premature

Vertical Roller Mill Operation in Cement Plant

The vertical roller mill (VRM) is a type of grinding machine for raw material processing and cement grinding in the cement manufacturing process. In recent years, the VRM

Cement Mill for Sale Buy Cement Ball MillVertical Roller Mill

Cement Mill Cement mills are the milling machines used in cement plants to grind hard clinker into fine cement powders. Cement ball mill and vertical roller mill are two most

important operation tips for cement vertical mill

Vertical mill is a equipment that grinds materials by relative rolling of a grinding roller on grinding disc. There are several aspects to the normal operation of the vertical mill: The material layer of Vertical mill The

Vertical Grinding Mill, Vertical Roller Mill Powder Making Mill

Vertical Grinding Mills Vertical Grinding Mills Contact Now +86- 1 2 Vertical Grinding Mills GKLM series vertical grinding mill is one advanced powder

Ball Miller and Verticle Miller for Cement Grinding

The vertical mill is divided into coal vertical mill, slag vertical mill and cement vertical mill according to the application. Cement vertical mill is pressurized by hydraulic system, and the pressure acts on the material

Operational parameters affecting the vertical roller mill

2017年4月1日With the introduction of the high compression machines such as High Pressure Grinding Rolls (HPGR), Vertical Roller Mills (VRM) and Horomills, efficiency of the grinding circuits was improved in terms of energy and downstream effects. Among these devices, vertical roller mills have an important position in cement and mining

Vertical Roller Mills

Vertical roller mills Overview Products What we offer Customer stories Vertical roller mills offer supreme grinding with high energy-efficiency Whether grinding raw coal, clinker, cement and/or slag, we have a

Our modern vertical roller mill takes you further

The OK™ Mill was originally designed for cement grinding. In 2017 we released the OK™ vertical roller mill for raw materials grinding. The OK™ Mill’s modular design comes with unique flexibility, showcasing parts

PROCESS CONTROL FOR CEMENT GRINDING IN VERTICAL

The power ingesting of a grinding process is 50-60% in the cement production power consumption. The Vertical Roller Mill (VRM) reduces the power consumption for cement grinding approximately 30-40% associated with other grinding mills. The process variables in cement grinding process using VRM are strongly nonlinear and having

Cement Vertical Mill for sale

Cement vertical mill is pressurized by hydraulic system, and the pressure acts on the material between the grinding roller and the grinding disc to achieve the purpose of grinding, vertical High grinding efficiency, 20

Grinding Mill m.mplcrusher

Based on abundant experience on producing vertical grinding mill and the latest technology from Taiwan &Germany, ZENITH developed the LUM Series Ultrafine Vertical Roller Mill, which gets high reputation from customers. MTM Medium Speed Trapezium Mill. Cement Mill is used to grind the hard, nodular clinker from the cement kiln into

VERTICAL CEMENT MILL Xinxiang Great Wall Machinery Co.,

Process introduction The GRMK vertical cement mill of CHAENG adopts a new generation of cement grinding technology, which integrates grinding, drying and powder selecting functions. It can save 30% of power per ton compared with traditional ball mill. At the same time, it has many advantages, such as less auxiliary equipment, multiple functions, small

Cement Mill Cement Ball Mill Vertical Cement Mill AGICO

Cement mill is the core equipment for grinding material after clinker production. Generally, the cement mill can be called cement grinding mill. Among production cost of cement manufacturing, grinding powder consumption takes 35%-40%. The cement grinding plant is a vital link to control cement quality.

Vertical Grinding Mill, Vertical Roller Mill Powder Making Mill

Vertical Grinding Mills Vertical Grinding Mills Contact Now +86- 1 2 Vertical Grinding Mills GKLM series vertical grinding mill is one advanced powder making mill through our engineer research and experience and bringing in advanced technology of the world.

Mutually standby multi-roll cement vertical roller mill

The invention relates to a mutually standby multi-roll cement vertical roller mill which is used for grinding materials and comprises a grinding disk, a plurality of roller groups, a plurality of swinging mechanisms and a hydraulic control device The grinding disk is used for storing materials, the roller groups are arranged on the grinding disk, each roller

(PDF) Performance Evaluation of Vertical Roller Mill

2017年9月11日Performance Evaluation of Vertical Roller Mill in Cement Grinding: Case Study ESCH Cement Plant Classifier max. rotor speed (rpm) 150. high pressure grinding rolls [Show full abstract

mpl Automatic mills All the products on DirectIndustry

Raymond grinding mill 4R3216. vertical for limestone stone. Final grain size: 44 µm 165 µm. Output: 3 t/h 5 t/h. Motor power: 37 kW. Raymond Mill is mainly used for non-flammable and non-explosive materials with Mohs’ hardness less than 7 and humidity less than 6% such as barite, calcite, marble, ceramics and glass.

1250 mesh bauxite grinding mill Popular 1250 mesh bauxite grinding mill

Vertical Bauxite Grinding Mill Raw Mill Cement Plant 325 1250 Mesh...1250 Mesh High Efficiency Vertical Bauxite Grinding Mill Machine Description The vertical grinding mill is widely used in such small and medium industries as mining, chemicals, building materials, metallurgy, refractories, pharmaceuticals, cement, etc.

Technical Notebook CEMENT ADDITIVES FOR VERTICAL

page 04 2. vertical mills introduction page 05 3. principles of vertical grinding systems page 053.1 vertical mill components page 063.2 how does a vertical mill work? page 07 4. new generation of grinding additives: ma.g.a./vm and ma.p.e./vm page 074.1 mill output increase page 074.2 quality and water demand optimisation page 08 5.

Operational parameters affecting the vertical roller mill

2017年4月1日With the introduction of the high compression machines such as High Pressure Grinding Rolls (HPGR), Vertical Roller Mills (VRM) and Horomills, efficiency of the grinding circuits was improved in terms of energy and downstream effects. Among these devices, vertical roller mills have an important position in cement and mining

Vertical Roller Mills

Vertical roller mills Overview Products What we offer Customer stories Vertical roller mills offer supreme grinding with high energy-efficiency Whether grinding raw coal, clinker, cement and/or slag, we have a

Our modern vertical roller mill takes you further

The OK™ Mill was originally designed for cement grinding. In 2017 we released the OK™ vertical roller mill for raw materials grinding. The OK™ Mill’s modular design comes with unique flexibility, showcasing parts

PROCESS CONTROL FOR CEMENT GRINDING IN VERTICAL

The power ingesting of a grinding process is 50-60% in the cement production power consumption. The Vertical Roller Mill (VRM) reduces the power consumption for cement grinding approximately 30-40% associated with other grinding mills. The process variables in cement grinding process using VRM are strongly nonlinear and having

Cement Vertical Mill for sale

The vertical mill uses the principle of material layer to grind the material with low energy consumption. The power consumption of the grinding system is 20% to 30% lower than that of the ball mill, and the power

Grinding Mill m.mplcrusher

Based on abundant experience on producing vertical grinding mill and the latest technology from Taiwan &Germany, ZENITH developed the LUM Series Ultrafine Vertical Roller Mill, which gets high reputation from customers. MTM Medium Speed Trapezium Mill. Cement Mill is used to grind the hard, nodular clinker from the cement kiln into

VERTICAL CEMENT MILL Xinxiang Great Wall Machinery Co.,

Process introduction The GRMK vertical cement mill of CHAENG adopts a new generation of cement grinding technology, which integrates grinding, drying and powder selecting functions. It can save 30% of power per ton compared with traditional ball mill. At the same time, it has many advantages, such as less auxiliary equipment, multiple functions, small

mpl Automatic mills All the products on DirectIndustry

Raymond grinding mill 4R3216. vertical for limestone stone. Final grain size: 44 µm 165 µm. Output: 3 t/h 5 t/h. Motor power: 37 kW. Raymond Mill is mainly used for non-flammable and non-explosive materials with Mohs’ hardness less than 7 and humidity less than 6% such as barite, calcite, marble, ceramics and glass.

Vertical Grinding Mill, Vertical Roller Mill Powder Making Mill

Vertical Grinding Mills Vertical Grinding Mills Contact Now +86- 1 2 Vertical Grinding Mills GKLM series vertical grinding mill is one advanced powder making mill through our engineer research and experience and bringing in advanced technology of the world.

Mutually standby multi-roll cement vertical roller mill

The invention relates to a mutually standby multi-roll cement vertical roller mill which is used for grinding materials and comprises a grinding disk, a plurality of roller groups, a plurality of swinging mechanisms and a hydraulic control device The grinding disk is used for storing materials, the roller groups are arranged on the grinding disk, each roller

(PDF) Performance Evaluation of Vertical Roller Mill

2017年9月11日Grinding and separation efficiency of vertical roller mill were evaluated. In addition to these, performance figures of vertical roller mill and conventional closed ball mill circuit...

1250 mesh bauxite grinding mill Popular 1250 mesh bauxite grinding mill

Vertical Bauxite Grinding Mill Raw Mill Cement Plant 325 1250 Mesh...1250 Mesh High Efficiency Vertical Bauxite Grinding Mill Machine Description The vertical grinding mill is widely used in such small and medium industries as mining, chemicals, building materials, metallurgy, refractories, pharmaceuticals, cement, etc.

Vertical Cement Mill CHAENG

CHAENG GRMK Vertical Cement Mill also called VRM cement mill, mainly used in the grinding production of cement clinker, integrating drying, grinding, grading, and conveying, which can meet the requirements of users for different output and different fineness grinding. Capacity: 30-250 t/h. Power: 25-30 KWh/t. Specific surface area: 330-380m²/Kg.