Prediction Of Grinding Media Wear In Sag Mills

Modeling and prediction of wear rate of grinding media

2020年8月3日Total media wear in grinding media is attributed to three main mechanisms, including abrasion, impact and corrosion. Abrasion and impact wear are

Effect of the operating parameter and grinding media on

2019年12月15日The wear rate of the lifter specimen is increased first and then decreased with mill speed and grinding media size. Increasing ball filling will increase the wear

Numerical prediction of wear in SAG mills based on DEM

2018年2月1日Semi-autogenous grinding (SAG) mill is widely used in the grinding process of coal and ores because of its strong applicability, large capacity and low

Numerical prediction of wear in SAG mills based on DEM

2018年4月15日Research on Non-Uniform Wear of Liner in SAG Mill. W. Wu, H. Che, Qianhua Hao. Materials Science. Processes. 2020. The numerical calculation method is

SAG Mill Grinding Circuit Design Mineral Processing

2016年6月6日Because SAG mills rely both on the ore itself as grinding media (to varying degrees) and on ore-dependent unit power requirements for milling to the transfer size, throughput in SAG circuits are variable.

Power Draw of Grinding Mills its Measurement and

1994年10月16日In recent years the Julius Kruttschnitt Mineral Research Centre (JKMRC) has developed mathematical models for accurately predicting the power draw of ball,semi-autogenous (SAG) and fully...

Prediction of tumbling mill liner wear: Abrasion and

2016年8月5日Liner wear occurs during the grinding process in tumbling mill. It has a significant influence on the overall economic performance of mills. It will be worthwhile to

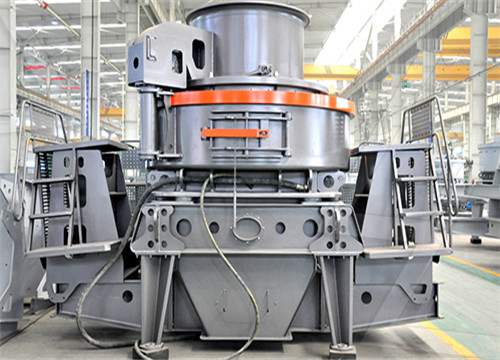

Grinding Media ball mills supplier

1. Cast grinding balls. Chromium content: 1% 28%. Hardness: HRC40-60. Diameter: 10mm-150mm. Features: after heat treatment, it has high hardness, grinding resistance

Numerical prediction of wear in SAG mills based on DEM

2018年4月15日Wear is a major operating problem for semi-autogenous grinding (SAG) mills. A credible and efficient numerical approach for accurately predicting wear within SAG mills can significantly reduce design time and improve grinding efficiency.

Effect of the operating parameter and grinding media on the wear

2019年12月15日The wear of lifter in ball mill directly affects the grinding efficiency and economic cost. However, how to evaluate the variation of wear process and predict the wear distribution of lifter is poo The wear of lifter in ball mill directly affects the grinding efficiency and economic cost.

Modeling and prediction of wear rate of grinding media in

2020年8月3日Total media wear in grinding media is attributed to three main mechanisms, including abrasion, impact and corrosion. Abrasion and impact wear are described as metal loss due to mechanical force on the grinding media. Erosion wear results from the friction between grinding media and particles.

Wear ofgrinding media in the mineral processing industry:

grinding environments in which grinding media are used. These include semiautogenous (SAG) .mills, rod mills, conventional ball mills, and tower mills. The different types ofgrinding media available for these grinding applications include heat-treated and as-rolled grinding rods, forged steel balls, cast steel balls, cast high chrome iron balls

Investigation of the effect of filling level on the wear and

2022年4月1日Snapshots of the grinding process in the SAG mill after operating for 4 revolutions, when the media filling level is 15%, and ore filling levels are set to ψore = 10%, ψore = 15%, ψore = 20%, ψore = 25%, and ψore = 30%. Furthermore, the mill power at different ore filling levels is figured here.

Prediction of tumbling mill liner wear: Abrasion

2016年2月28日Liner wear occurs during the grinding process in tumbling mill. It has a significant influence on the overall economic performance of mills. It will be worthwhile to know the effect of...

Numerical prediction of wear in SAG mills based on DEM

2018年4月15日Research on Non-Uniform Wear of Liner in SAG Mill. W. Wu, H. Che, Qianhua Hao. Materials Science. Processes. 2020. The numerical calculation method is used to analyze the wear of the liner of the general structure of a semi-autogenous mill in the axial direction, and the non-uniform wear of each area of the liner.

Prediction of tumbling mill liner wear: Abrasion and impact effects

2016年8月5日Liner wear occurs during the grinding process in tumbling mill. It has a significant influence on the overall economic performance of mills. It will be worthwhile to know the effect of mill operating parameters on the liner wear intensity.

(PDF) Prediction of grinding-mill power

1992年1月1日Prediction of grinding-mill power January 1992 Authors: S. Morrell Abstract A summary is given of the most recent findings of a continuing research project that has as its aim the development of...

Comminution testing JKTech University of Queensland

JKTech offers a unique testing methodology for the quantitative characterisation of steel media wear in SAG and Ball mills. to produce one total wear prediction. 3-4 kg of material in the correct size fraction (-850+300 µm) per combination of grinding media and material type. Grinding media as provided by client, preferably 50 mm

Effect of operating condition changes on the collisional

2019年3月1日Prediction of slurry grinding due to media and coarse rock interactions in a 3D pilot SAG mill using a coupled DEM + SPH model P. Cleary, R. Morrison, M. Sinnott Materials Science 2020 9 Operation Analysis of a SAG Mill under Different Conditions Based on DEM and Breakage Energy Method

BF[07-12] PDF Mill (Grinding) Screw

BF[07-12] Read online for free. Share with Email, opens mail client

(Received: February 1, 2016; Accepted: November 4, 2016)

to simulate the high stress abrasion conditions experienced in production ball mills. It gives accurate predictions of the service life of wear resistant alloys in mill liner and grinding media applications. In this stone the BMA test methodology was applied to investigate the wear rates of four grades of grinding media using two small laboratory

Grinding Media ball mills supplier

1. Cast grinding balls. Chromium content: 1% 28%. Hardness: HRC40-60. Diameter: 10mm-150mm. Features: after heat treatment, it has high hardness, grinding resistance and no loss of roundness. Application: cast grinding balls are widely used in ball mill grinding systems in mining, cement, building materials, chemical industry and other fields.

Modeling and prediction of wear rate of grinding media in

2020年8月3日Total media wear in grinding media is attributed to three main mechanisms, including abrasion, impact and corrosion. Abrasion and impact wear are described as metal loss due to mechanical force on the grinding media. Erosion wear results from the friction between grinding media and particles.

Effect of the operating parameter and grinding media on the wear

2019年12月15日The wear of lifter in ball mill directly affects the grinding efficiency and economic cost. However, how to evaluate the variation of wear process and predict the wear distribution of lifter is poo The wear of lifter in ball mill directly affects the grinding efficiency and economic cost.

Wear of grinding media in the mineral processing industry: An overview

Within the mineral processing industry, a range of grinding conditions exists which include semiautogenous grinding (SAG), rod milling, and conventional ball milling. Each of these mill environments presents a unique environment for grinding media, requiring the application of specific physical and chemical properties for optimum grinding media

Prediction of tumbling mill liner wear: Abrasion

2016年2月28日Liner wear occurs during the grinding process in tumbling mill. It has a significant influence on the overall economic performance of mills. It will be worthwhile to know the effect of...

Numerical prediction of wear in SAG mills based on DEM

2018年4月15日Research on Non-Uniform Wear of Liner in SAG Mill. W. Wu, H. Che, Qianhua Hao. Materials Science. Processes. 2020. The numerical calculation method is used to analyze the wear of the liner of the general structure of a semi-autogenous mill in the axial direction, and the non-uniform wear of each area of the liner.

Comminution testing JKTech University of Queensland

JKTech offers a unique testing methodology for the quantitative characterisation of steel media wear in SAG and Ball mills. to produce one total wear prediction. 3-4 kg of material in the correct size fraction (-850+300 µm) per combination of grinding media and material type. Grinding media as provided by client, preferably 50 mm

(PDF) Prediction of grinding-mill power

1992年1月1日Prediction of grinding-mill power January 1992 Authors: S. Morrell Abstract A summary is given of the most recent findings of a continuing research project that has as its aim the development of...

On dry SAG mills end liners: Physical modeling, DEM-based

2019年9月1日Numerical prediction of wear in SAG mills based on DEM simulations. Powder Technol. (2018) P. Toor et al. Designing liners for performance not life. Mine. Eng. (2013) as well as size and shape of grinding media, thereby may causing errors. Discrete element method (DEM) can simulate the motion and interaction of particle

Industrial Vertical Stirred Mills Screw Liner Wear

2021年4月10日The stone analysis media flow, energy absorption, flow structures, wear, mixing, and transport efficiency, and allows a good and wide understanding of the performance of vertical stirred mills. For the

Prediction of tumbling mill liner wear: Abrasion and impact effects

2016年2月28日Liner wear occurs during the grinding process in tumbling mill. It has a significant influence on the overall economic performance of mills. Prediction of tumbling mill liner wear: Abrasion and impact effects Show all authors. M Akhondizadeh 1. Radziszewski, P, Varadi, R, Chenje, T. Tumbling mill steel media abrasion wear

BF[07-12] PDF Mill (Grinding) Screw

BF[07-12] Read online for free. Share with Email, opens mail client

Prediction of tumbling mill liner wear: Abrasion and impact effects

2016年2月28日Liner wear occurs during the grinding process in tumbling mill. It has a significant influence on the overall economic performance of mills. It will be worthwhile to know the effect of mill operating parameters on the liner wear intensity.

Grinding Media ball mills supplier

1. Cast grinding balls. Chromium content: 1% 28%. Hardness: HRC40-60. Diameter: 10mm-150mm. Features: after heat treatment, it has high hardness, grinding resistance and no loss of roundness. Application: cast grinding balls are widely used in ball mill grinding systems in mining, cement, building materials, chemical industry and other fields.